As a last minute addition for safety, they added an 'H0' command to the start of the program. So when you program G384 in MDI or from a program it jumps into program 9010 and does all that lot.

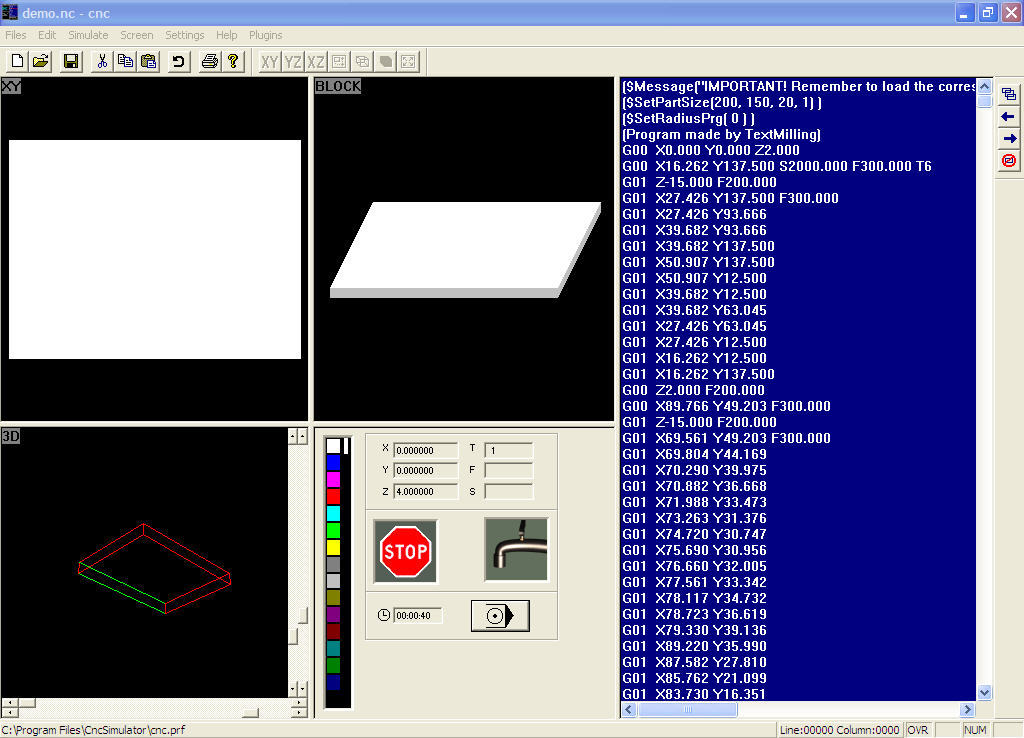

#PROGRAMA DE CNC SIMULATOR HOW TO#

How to set zero return position for fanuc controls. FANUC – Training Centre Syllabus: CNC OPERATION AND PROGRAMMING-TURNING AND MILLING A thorough knowledge of CNC Part Programming is essential to engineers and operators from machine tool builders and end-users.

Instead of calling the custom macro in the usual manner (typically using G65 or G66 with the program number), it is improve cnc programs with user-defined g, m codes 10 M codes from M006 to M99999999""G65P (program number) L (repetition count) " 9001 to 9009 6080 to 6089 Set G or M code that calls program specified in the parameter "Max. Parameter 6050 is the G code for program 9010. Macro Gat frezen I example fanuc mill code, fanuc macro program, g65 fanuc, fanuc m codes, c++ code for cnc, More Courses ›› View Course Fanuc example picking program - Pickit 2. Choose from the table below the character to engrave.

is read as a modal data on M series and a commanded data on T series. I don’t find this to be a good practice because it is confusing. One of the most powerful combinations of programming functions is found in the typical Fanuc use of G65 to pass information into "nests" and use system, common, and local variable table contents for a multitude of tasks to make machining safer and more productive. Converts Common Variables between formats. Instead of calling the custom macro in the usual manner (typically using G65 or G66 with the program number), it is improve cnc programs with user-defined g, m codes H = Height of text.

0 kommentar(er)

0 kommentar(er)